We know people carpooling reduces carbon emissions, so why not promote increased carpooling for products?

A product’s journey to your local store or to your door starts when a shipping container is delivered to a factory where it is filled with products. This shipping container then travels via boat, train, and/or semi. Maximizing the number of units that fit in each shipping container reduces average greenhouse gas emissions to ship each unit. Just like carpooling is more efficient, putting more units in each container is more efficient.

In other words, only slightly more energy is necessary for a semi to haul 2,000 units rather than 1,000 units. Doubling the number of units while only increasing the energy slightly can lower the average greenhouse gas emissions by nearly 40% to 50%, which is a dramatic leap toward sustainability.

The company's innovative approach stands as a testament to the fact that sometimes thinking "outside the box" – quite literally in this case – can lead to practices that are both economically viable and environmentally responsible.

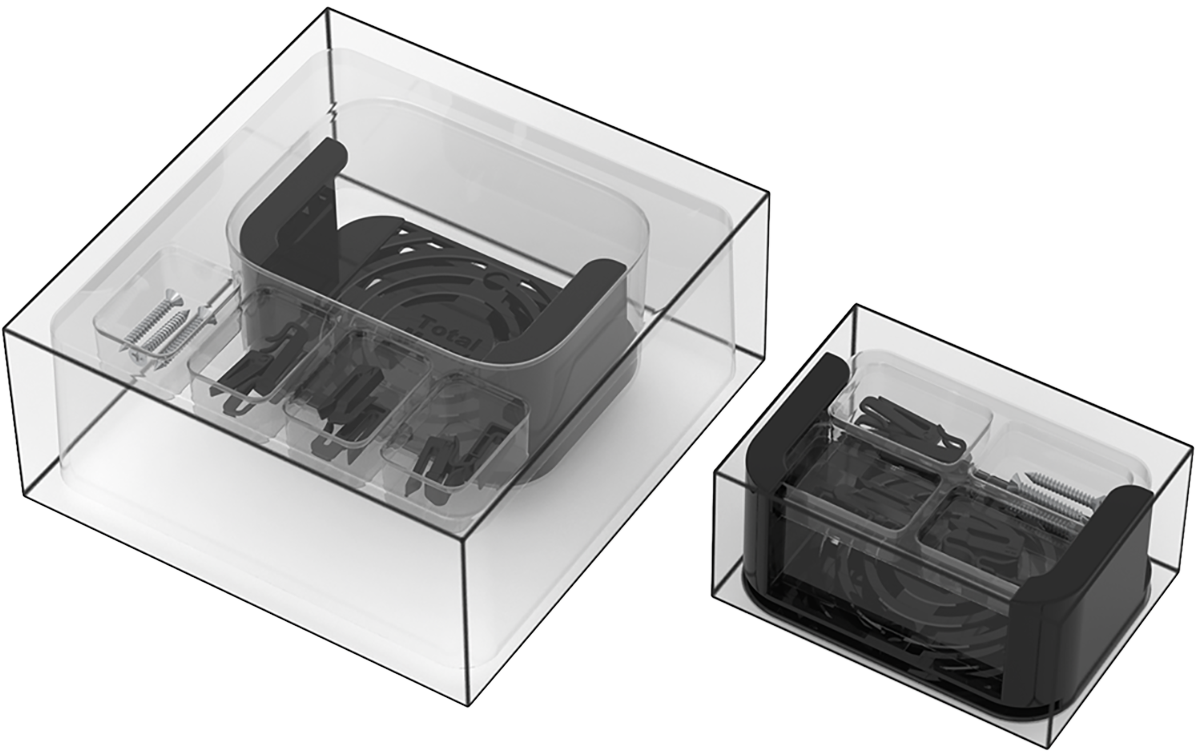

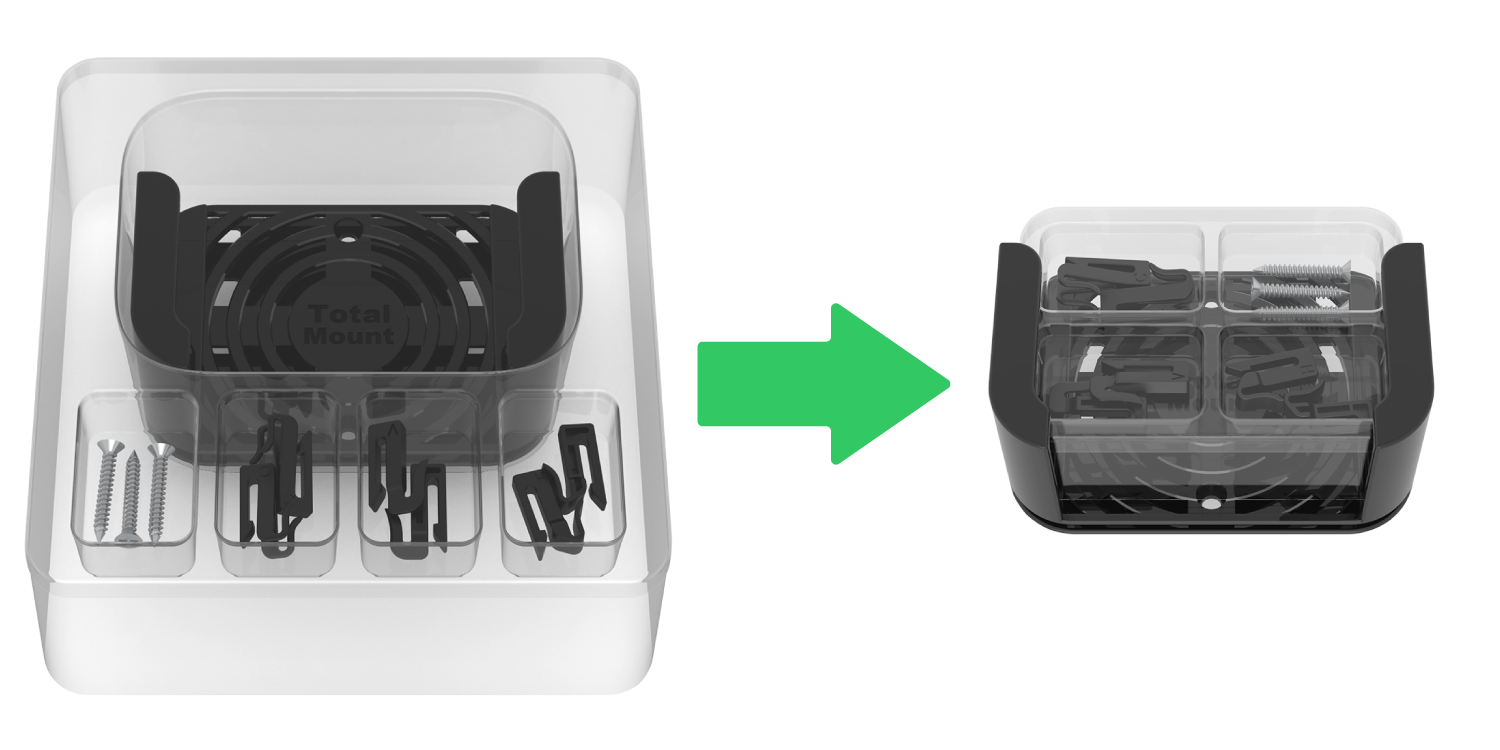

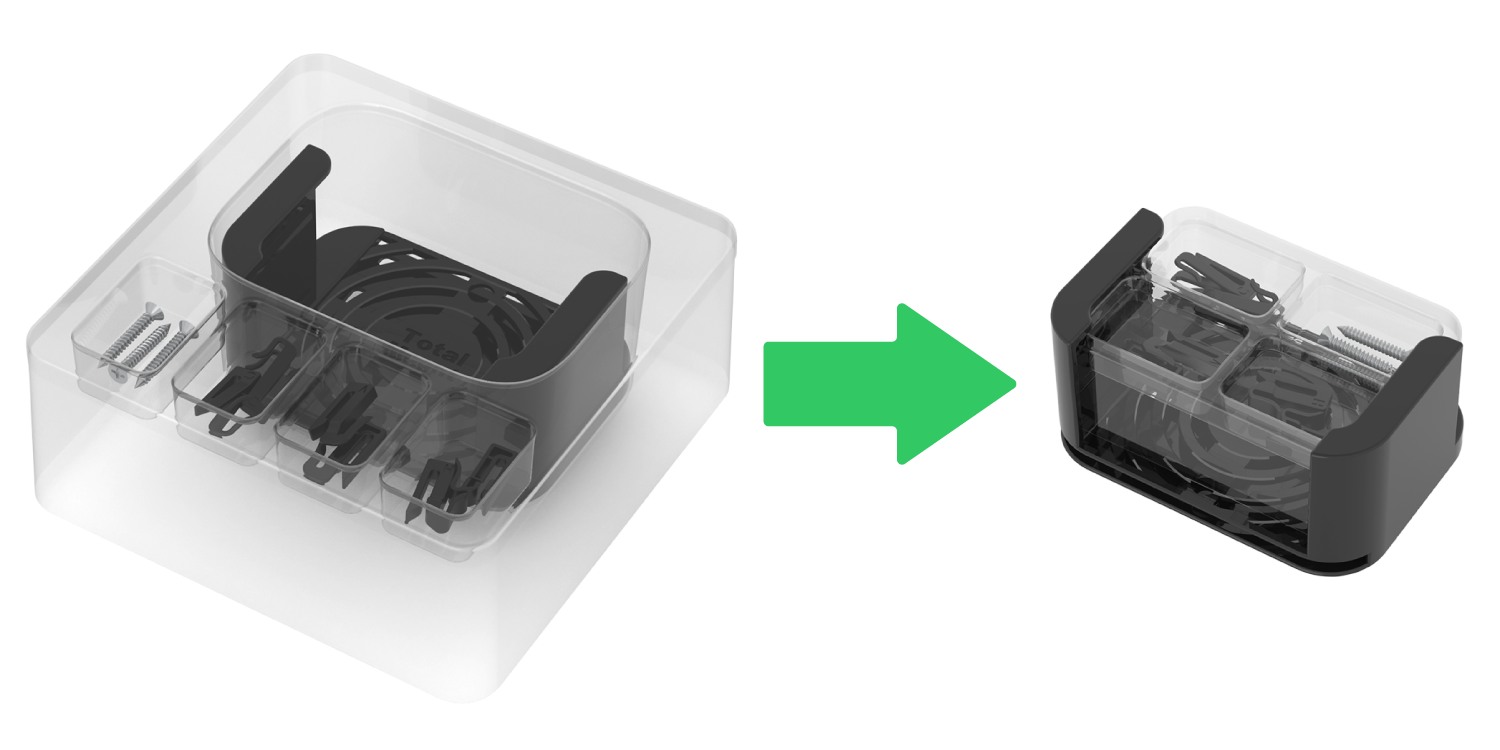

TotalMount maximized the number of units that fit in each vehicle by minimizing the volume of each packaged product.

Any time you see empty space inside of product packaging, there is likely an opportunity to simultaneously eliminate unnecessary shipping pollution and expenses.

239% Better Shipping Efficiency